The Significant Benefits of CNC Precision Machining

Daily technological advancements and the expanding global market pose new concerns for the world manufacturing sector. This is why it's crucial for manufacturers in every manufacturing sector, from the automotive to the aerospace, to use precise and safe manufacturing techniques.

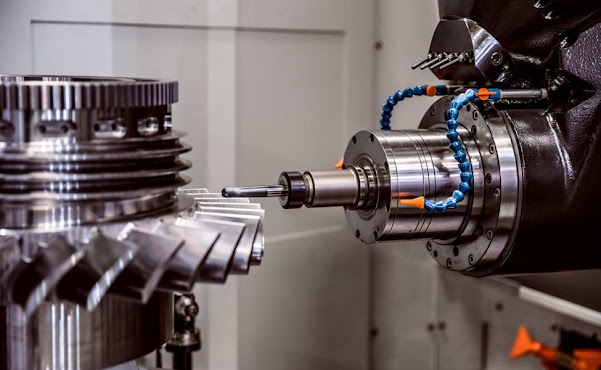

CNC precision machining is the process of removing material from a sheet or block of material and cutting it into precise shapes and sizes for use in various manufacturing industries. Blades and hammers were used to accomplish this in the beginning. Still, technology has allowed the industry to utilize computer numerical controlled (CNC) machines that work with mills and grinders for a more precise result.

There are a number of reasons why precision machining is a highly sought-after process in global manufacturing, making it one of the most significant techniques used in the machining industry. The top five Significant Benefits of CNC Precision Machining are listed below:

Higher Accuracy and Precision

Precision is one of the main advantages of using CNC machining over manual processes. Without a skilled operator's constant supervision, it is possible to produce parts that adhere to exact specifications.

Because CNC milling machines use computer instructions to fabricate parts, human error is eliminated. The operator of the CNC machine does, however, still have some control over the manufacturing process.

The accuracy of the CNC milling project is largely operator-dependent. The control of the operating environment and cutting tool calibration rests with the operator. Additionally, they must be able to spot when the tooling is becoming too worn down and unable to produce the best results when in contact with raw materials. But overall, there is much less chance of human error.

Complex CNC machining parts can be made fairly with tolerances as low as 0.004 mm. High-precision CNC machined components are essential to the aerospace and defence industries. The ability to produce such exact CNC machining parts following specifications may save lives.

Lower Error Rate and Greater Accuracy

Precision-turning machines avoid the possibility of human error seeping into the manufacturing process and resulting in defects because they operate autonomously without any manual intervention. Machines can deliver greater accuracy with no errors when codes and software programs govern the entire process.

Additionally, unless changed purposefully, these inputs remain unchanged throughout the production process, cycle after cycle, maintaining consistency in the final products. Further, the machines can run nonstop for extended periods of time without sacrificing the quality of the work they produce.

Superior output and scalability

Production can begin once the operator has programmed the machine with the required design specifications. It takes no time to produce CNC machining parts once the CNC machine has begun a production run.

Modern CNC machines are very scalable and can produce large quantities of parts. A CNC machine can be programmed to create a single item or many, which distinguishes them from traditional machines and manual production methods. There are no restrictions on the number of parts you can produce, enabling businesses to use their assets and budgets better.

Able to create even the most complex components

Any component you can imagine can be produced using CNC machining. These tools are capable of a wide range of CNC milling and fabrication tasks, such as shearing, flame cutting, punching holes, and welding metal sheets.

CNC machines can be used to create incredibly complex shapes due to their incredibly high level of precision.

Cost-effective

CNC precision machining can significantly lower manufacturing costs because there is less chance of making mistakes and delivering subpar results. Since it ensures accurate results, it gives manufacturers a clear financial plan for production and does away with the need to set aside a budget for contingencies. It also has the potential to lower labour costs.

CNC Machining with Gemsons

At Gemsons, we are enthusiastic about our business and the support we give to our customers. As a result, we have made significant investments in the most recent developments in CNC machining and have a team of highly qualified engineers.

We are sure that we can offer our clients the best CNC precision machining services, and we'll always provide the highest-quality customer service.

Comments

Post a Comment